垂直回转式仓储系统 VS. 水平回转式仓储系统:并列对比

电动汽车的制动能量回收系统可以回收部分动能,转化为电能储存。 #生活常识# #环保节能技巧# #电动汽车#

卡迪斯Kardex Remstar 卡迪斯Kardex Remstar 卡迪斯Kardex Remstar是全球领先的自动化仓储和拣选方案供应商。我们量身定制的内部物流解决方案使您可以以最佳方式利用您的仓储空间,提升效率,减少成本,并让您的仓库具备可拓展性,可随业务发展而发展。

卡迪斯Kardex Remstar 卡迪斯Kardex Remstar 卡迪斯Kardex Remstar是全球领先的自动化仓储和拣选方案供应商。我们量身定制的内部物流解决方案使您可以以最佳方式利用您的仓储空间,提升效率,减少成本,并让您的仓库具备可拓展性,可随业务发展而发展。 垂直回转式仓储系统 VS. 水平回转式仓储系统:并列对比

垂直回转式式仓储系统 VS.水平回转式仓储系统:并列对比

Vertical vs. Horizontal Carousels: A Side-by-Side Look

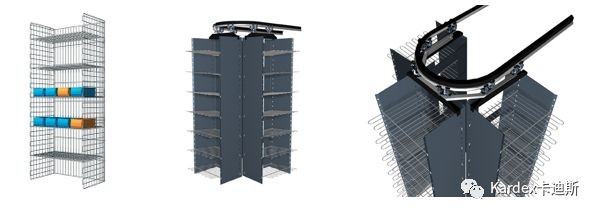

垂直回转式仓储系统

水平回转式仓储系统

尽管名称相似,但当您仔细观察时,垂直回转式仓储系统和水平回转式仓储系统的自动化仓储和检索技术有很大不同。最明显的区别在于机器的运行方式。根据它们的命名-垂直回转式仓储系统垂直旋转,水平回转式仓储系统水平旋转。但当涉及到这两种动态仓储和检索系统时,还有许多的方面要讨论。

Although similar in name, Vertical Carousels and Horizontal Carousels, are dramatically different automated storage and retrieval technologies when you take a closer look. The most obvious difference is in the way the machines operate. Per their naming - Vertical Carousels rotate vertically and Horizontal Carousels rotate horizontally. But there is WAY more to talk about when it comes to these two dynamic storage and retrieval beasts.

垂直回转式仓储系统说明:垂直回转式仓储系统是一系列固定位置连接到链条驱动的载物架。它由一个电机驱动运行,以垂直循环的方式将载物架传送到轨道的前后两个方向,类似于摩天轮。产品通过带有工作台的符合人体工程学的开口进行仓储或检索。

Vertical Carousels explained: vertical carousels are a series of carriers attached in fixed locations to a chain drive. Movement is powered by a motor, which sends the carriers in a vertical loop around a track in both forward and reverse directions—similar to a Ferris wheel. Goods are stored or retrieved through an ergonomically positioned access opening with a work counter.

水平回转式仓储系统说明:水平回转式仓储系统带由一个椭圆形轨道组成,用于支撑带架子的物料箱。位于椭圆形轨道内的电机水平驱动轨道周围的载物架;停在预先指定的开口,用于仓储或检索产品。

Horizontal Carousels explained: a horizontal carousel consists of an oval track supporting rotating bins with shelves. A motor located inside of the oval track powers the carriers around the track horizontally; stopping at a pre-designated access point for storage or retrieval of goods.

这两种自动化技术都是从20世纪50年代开始出现的,并且经常被不公平地归类为“ASRS恐龙”,因为没有什么比这更离谱了。事实上,它们丰富的历史和物料处理经验使它们成为稳定可靠的仓储设备。在它们的发展过程中,各种各样的设计调整和改进确保了这些可靠的动态仓储设备继续提供现代化、世界级的制造和配送设施,提高了物料处理效率,例如:

节省了60%至75 %的地面仓储空间 60 – 75% Floor Space Savings 降低了2/3的劳动力 2/3 Less Labor 99.9%的分拣正确率 99.9% Pick Accuracy 提高吞吐量 Increased Throughput 高库存控制 Higher Inventory ControlBoth automated technologies have both been around since the 1950's and are often given the unfair categorization of "ASRS dinosaurs" when nothing could be farther from the truth. In reality, their rich history and experience in material handling makes them stead fast and reliable storage devices. A variety of design tweaks and improvements over their life time have ensured these loyal dynamic storage units continue to deliver modern, world class manufacturing and distribution facilities improved material handling efficiencies such as:

一般规模 General Dimensions

两种设备的形状通常都是矩形的,垂直回转式仓储系统宽约1.8至4.3米,深约1.2至1.5米;水平回转式仓储系统长约5.8至46.6米。不同之处在于,两个仓储系统都是在宽度维度上运行的;使得垂直回转式仓储系统宽而浅,水平回转式仓储系统窄而长。

Both units are generally rectangular in shape with vertical carousels ranging 6 to 14 feetwide by 4 to 5 feet deep and horizontal carousels 19 to 153 feet long. The difference here is that both carousels are accessed on the width dimension; making vertical carousels wide and shallow and horizontal carousels narrow and long.

另一个大的区别是设备高度,垂直回转式仓储系统的起始高度超过约2.1米,最高可达约9.8米;而水平回转式仓储系统的起始高度超过约2.1米,但最大高度约为4.1米。虽然水平回转式仓储系统对于天花板高度低于约4.6米的区域确实是一个不错的选择,它们可以为更高的天花板堆叠两层(或三层),但关于这点我们之后再进行分析。

Another big differenec is unit height – vertical carousels start at just over 7 feet and can reach up to 32 feet tall where as horizontal carousels start at just over 7 feet, but have a max height of 13.5 feet. While horizontal carousels are indeed a good option for areas with ceiling heights under 15 feet – they can be double (or triple) stacked for higher ceilings – but more on that later.

产品处理 Products Handled

设备的最终占地面积总是取决于您需要仓储的产品大小和重量,紧接着是您拥有的产品数量。

The ultimate footprint of the unit always starts with the size and weight of the product you need to store – and then how much of it you have.

尺寸 Size:

垂直回转式仓储系统在约14.9到43.9米宽、约5.2到7.3米深的料斗上仓储产品。料斗宽度大约比整体单位宽度短约0.6米,从而在料斗两侧为轨道留出一定的空间。料斗的高度可以在约2.4米到5.8米之间。料斗可以进一步细分为额外的货架,用于管理较小的产品。在高密度仓储环境中,可以使用手提箱、容器、物料盒或抽屉来组织较小的零件。

Vertical carousels store items on carriers ranging from 49 to 144 inches wide by 17 to 24 inches deep. The carrier width is roughly 2 feet shorter than the overall unit width allowing some room on either side of the carrier for the track. The height of the carrier can range from 8 to 19 inches. Carriers can be further subdivided with additional shelves for management of smaller items. Totes, containers, boxes or drawers can be used to organize smaller parts in a high density storage environment.

垂直回转式仓储系统料斗 Vertical Carousel Carriers:

水平回转式仓储系统将产品仓储在悬挂于高架轨道上的料架中。料架可以是约7.5、9.9或11.3米宽,约5.5、6.7或7.3米深。料架高度从约1.8到3.7米不等,并决定整个装置的高度。可以使用中间的架子来划分载物架,以便为携带较小物品的手提箱、容器或物料盒实现理想的自定义仓储位置。

Horizontal carousels store items in carriers that hang from an over head track. Carriers can be 24.5,32.5 or 37 inches wide by 18, 22 or 24 inches deep. The carrier height ranges from 6 to 12 feet and determines the height of the overall unit. Carriers can be divided using intermediate shelving to create custom storage locations ideal for totes, containers or boxes holding smaller items.

水平回转式仓储系统料架 Horizontal Carousel Carriers:

Weight 重量:

产品重量在您的自动化仓储技术选择中也是一个变量。垂直回转式仓储系统每台可承受1430磅的重量;而水平垂直回转式仓储系统每台可承受2000磅的重量。在某些情况下,几磅的差距会使情况大不相同。

Product weight can also be a variable in your automated storage technology selection. Vertical carousels can handle weights up to 1,430 pounds per carrier; while horizontal carousels can handle up to 2,000 pounds per carrier. In some cases a few pounds can make all the difference.

所以...哪一种适合您?

So...Which One Is Right For You?

既然您已经了解了基本情况,应该使用哪一种?这种选择并不是总能十分明确,但是可以参考以下四点作为考虑方向…

Now that you know the basics – which one should you use? Well it's not always so clear cut – but let me give you four things to consider...

考虑1:物理空间

Consideration#1: Physical Space

仓库的物理空间(特别是天花板高度)是决定使用垂直回转式仓储系统和水平回转式仓储系统的主要考量因素。相比于垂直回转式仓储系统,较低的天花板高度可能更适合水平回转式仓储系统。不过,如果空间真的很紧,同时您需要最大的立方容量,垂直回转式仓储系统可能是更好的选择。即使在天花板较低的高度,垂直回转式仓储系统也比水平回转式仓储系统提供更多的容量。另一种选择是建造一个高的附加外部围墙来容纳垂直回转式仓储系统,并在现有的外墙上开一个开口——这比您想象的更常见——尤其是对于空间不足的低天花板设施。这一切都是关于您所拥有的物理空间和您所需要的空间(仓储密度)的平衡。

The physical space of your warehouse is a main consideration when it comes to deciding between avertical and horizontal carousel – specifically ceiling height. A lower ceiling height might mandate a horizontal carousel over a vertical carousel. Although if space is really tight and you are looking for maximum cubic capacity a vertical carousel might be the better option. Even at a lower ceiling height as vertical carousels provide a bit more capacity when compared to horizontal carousels. Another option is to build a tall attached exterior enclosure to house the vertical carousels and punch an access opening through an existing exterior wall – this is more common than you'd think - especially for low ceiling facilities that are out of space. It's all about the balance of the physical space you have and the space (storage density) you require.

考虑2:分拣速度

Consideration#2: Picking Speed

另一个考虑因素是系统吞吐量需求——这取决于您特定的应用。您需要多快才能将产品从系统中分拣出可能决定了适合您的最佳技术。吞吐量十分依赖于系统配置(布局和流程)、库存位置(开槽)、订单配置属性(单行与多行)、分拣策略(单订单或批量分拣)等。

Another consideration is the system throughput requirement - which is dependent on your specific application. How fast you need to get product out of the system might determine the best technology for you. Throughput rates are highly dependent on the system configuration (layout and process), inventory locations (slotting), order profile (single line vs multi), picking strategy (single order or batch picking) etc.

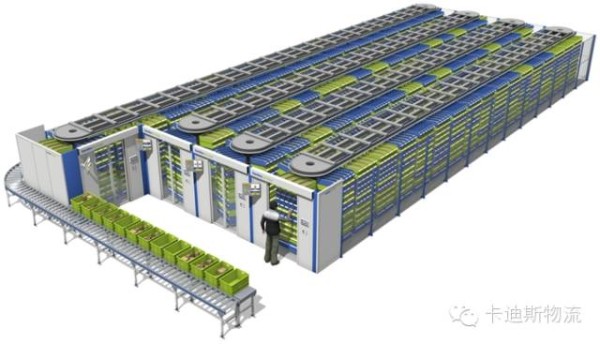

回转式仓储系统通常被布置成工作站或分离舱。操作员在分离舱内工作,从每台机器中分拣仓储的产品来完成订单——通常遵循指示灯或语音的分拣命令。自动仓储和检索系统的一个主要优点是货物到人的传送。所有仓储的产品都直接交付给操作员,大大减少了行走和搜索时间,从而提高了订单分拣的吞吐量。

Carousels are generally arranged into work stations, or pods. An operator(s) works within the pod picking stored product from each machine to fill orders – usually following light or voice directed picking commands. One of the main advantages to automated storage and retrieval systems is the good to person delivery. All stored goods are delivered directly to the operator, significantly reducing walk and search time and therefore increasing order picking throughput rates.

在设计工作站时,请务必考虑操作员步行到设备的时间。垂直回转式仓储系统通常以一条直线(2行或3行)并排排列。相邻排列3个垂直回转式仓储系统可以快速创建约11米(以上)的工作区。当有4个或更多的垂直回转式仓储系统时,您通常会看到它们按2x2面对面排列。这使得操作员可以在工作站的中间工作,轻松地进入4个单元;有一个约为7.3米而不是约为14.6米的步行区。在高吞吐量的应用中,每一步都很重要。

A word of caution when designing a workstation, always consider the operator walk time to the units. Vertical carousels are generally laid out in a straight line – 2 or 3 – in row next to one another. Arranging 3 vertical carousels next to each other can quickly create a 36 foot (plus) work area. When there are 4 or more vertical carousels you usually see them arranged 2 by 2; face to face. This allows the operator to work in the middle of the work station and access all 4 units easily; with a 24 foot walking area, instead of 48 feet. In high throughput application, every step counts.

对于高吞吐量,水平回转式仓储系统也布置在工作站或分离舱中;但这里的区别在于开口是可变的,可以调整以创建最有效的布局。当并排使用两个水平回转式仓储系统时,操作员可以在一个拐角中访问每台水平回转式仓储系统,创建一个只有约为1.5或1.8米的小型工作站。当多个水平回转式仓储系统放置在一个工作站中时,中间的水平回转式仓储系统可以从前方进行存取,同时旁边的机器可以在侧面开口进行访问,从而为操作员创建一个非常紧密的工作站。

For high throughput, horizontal carousels are also arranged in workstations or pods; but the difference here is the access point is variable and can be adjusted to create the most efficient layout. When using 2 horizontal carousels side by side, the operator can access each carousel at an angle, creating a small workstation of only 5 or 6 feet. When multiple horizontal carousels are positioned in a workstation the center carousels can be pushed back and accessed from the front, while the side ones can be directed to stop on a side or angle – creating a very tight workstation for the operator.

有了正确的配置和流程,水平回转式仓储系统可以以更高的吞吐量传送;但反过来,它们比一台水平回转式仓储系统占用更多的空间。所以在吞吐量和存储密度之间需要权衡。

With the right configuration and process in place, horizontal carousels can deliver at higher throughput rates; but conversely they take up more floor space than ahorizontal carousel. So there's a tradeoff between throughput and storage density.

考虑3:产品组合

Consideration#3: Product Mix

产品组合的稳定性也是一个要考虑的决策标准。垂直回转式仓储系统为固定产品尺寸提供高度密集的仓储空间。虽然中间货架可以从今天约0.6米高的产品改为明天约1.2米的产品,但载物架尺寸有限制。水平回转式仓储系统更容易适应不断变化的产品组合。能够根据需要添加或移除载物架,并可调整分拣灯。

The stability of your product mix is also a decision criteria to consider. Vertical carousels provide highly dense storage for static product sizes. While intermediate shelves can be changed from storing 2 inch tall product today to 4 inch products tomorrow; there are carrier size limitations. Horizontal Carousels are easier to adjust to a changing product mix. Carrier shelving can be added or removed and pick lights can be adjusted as needed.

考虑4:成本

Consideration#4: Cost

一切都取决于它的成本和您的预算。总的来说,水平回转式仓储系统是每立方英尺仓储成本最低的选择。虽然价格总是作为主要考虑因素,但最终不是价格——而是找到一个最佳的系统来满足您现在和将来的需求。您的决定应该基于您拥有的空间、应用的要求和成本。请物料处理专家分析您的应用,比较两种解决方案的成本,并帮助您权衡优缺点。

It all comes down to how much does it cost and what's your budget. Overall, the horizontal carousel is the least expensive option per cubic foot stored. While price is always a main consideration, it's never all about price in the end - it's about finding the best system to meet your needs now and into the future. Your decision should be based on the space you have, the requirements of your application and the cost. Ask a material handling specialist to analyze your application, provide you a comparison cost for both solutions and help you weigh the pros and cons.

声明: 本文由入驻搜狐公众平台的作者撰写,除搜狐官方账号外,观点仅代表作者本人,不代表搜狐立场。

回首页看更多汽车资讯网址:垂直回转式仓储系统 VS. 水平回转式仓储系统:并列对比 https://www.yuejiaxmz.com/news/view/711583

相关内容

垂直旋转库【仓库洞察】划重点!三个步骤优化仓储空间!

智慧物流:京东分布式仓储体系

WMS自动化仓储管理系统

智慧仓储管理系统:自动化与实时管理的未来

电动垂直升降储物架系统五金

短租临时仓储

立体仓储

智能仓储管理系统如何通过自动化设备提升供应链管理效率?

家庭小仓库储物间租赁,家庭仓库出租